Oil and Gas Monitoring Systems Prevent and Detect Damages

The oil and gas sector is experiencing significant changes through the implementation of the Internet of Things (IoT). This is particularly evident in pipeline monitoring, where innovative smart systems minimize failure risks and maintain pipe integrity for companies.

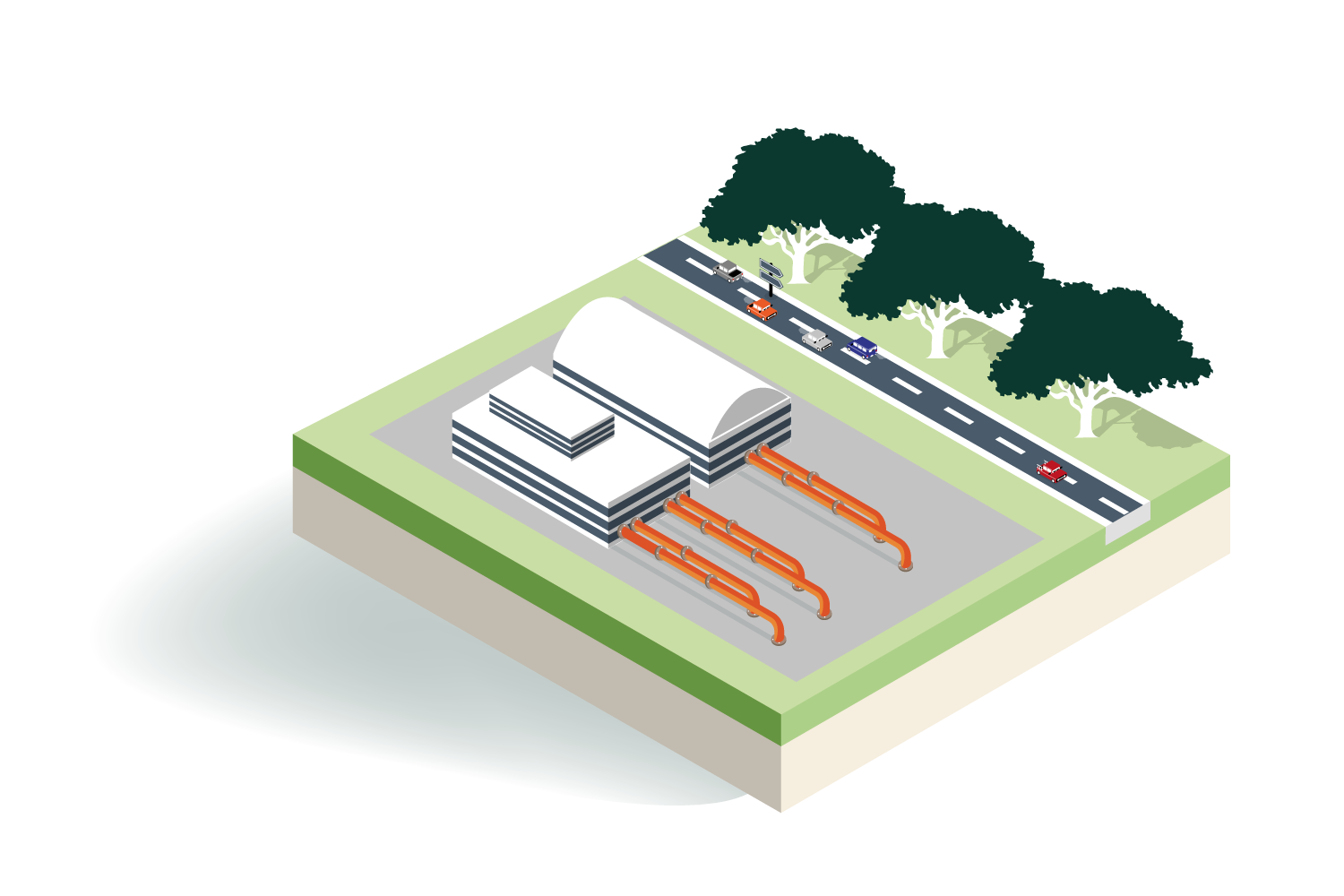

Pipelines are crucial pieces of infrastructure that are responsible for the transportation of oil and gas, water supplies, and substances within chemical plants. They are vital in supporting the global economy, but their failure can have catastrophic consequences, endangering human lives, profits, and the environment.

Fortunately, the IoT is offering new solutions for pipeline monitoring. By leveraging the connectivity provided by the IoT, companies can implement systems that continuously monitor the condition of their piping. Pipelines monitoring systems are composed of various components, including sensors, data acquisition systems, data transfer systems, data management systems, and data analysis tools.

To accomplish this, companies utilize various sensor systems that are capable of independently verifying crucial factors. These factors may include pressure, temperature, flow velocity, power failure, and humidity. Moreover, the monitoring parameters can encompass a wide range of variables, such as water level, presence of corrosive gases, flow rate, general water quality, pressure, temperature, and pipe deformation.

Furthermore, the pipeline monitoring system can be expanded to include other environmental parameters. These parameters may include PM10, carbon monoxide, nitrogen dioxide, ozone, and sulfur dioxide, all of which play a vital role in air quality assessment.